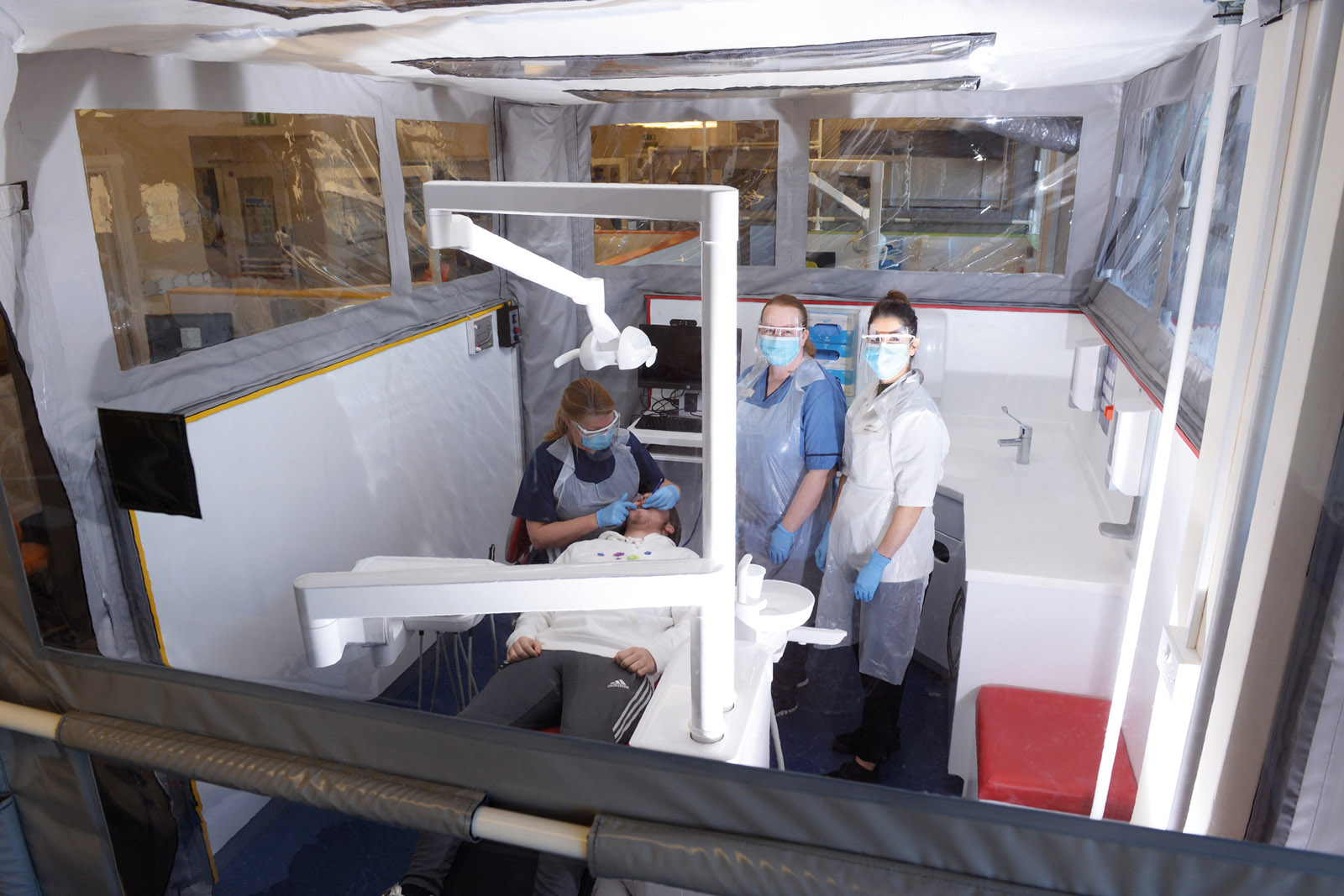

Dental hospital installs ‘AGP pods’

Special pods are being installed at Dundee Dental Research Hospital and School, allowing aerosol generating procedures (AGPs) to be undertaken safely in otherwise open clinics.

Twenty SafeClinic pods, made by Starn Group, the Dundee-based energy services company specialising in hazardous working environments, are in the process of being set up after £248,000 in funding from NHS Tayside was secured by the hospital and school management.

A spokesperson told Scottish Dental magazine: “Dundee Dental Research Hospital and School is in the process of having 20 SafeClinic pods installed to allow AGPs to be undertaken in a safe environment on open clinics. Each pod has a metal frame with flame-retardant PVC walls and ceiling and an airlock door, converting the dental unit into a Class N negative pressure isolation room.

“Each unit takes around eight hours to install and is compliant with NHS guidelines, WHO guidelines and hospital design and installation standards with a key aspect being that the air changes per hour can be varied from a minimum of 12 per hour, which drastically cuts the fallow time between patients.

“Dr Brian Stevenson, Acting Clinical Director, and Joanne Cowburgh, Clinical Care Group Manager, secured funding for this project from NHS Tayside in recent months to allow AGPs to continue during the COVID pandemic.”

Starn Group makes a range of equipment to deliver safe working environments in traditionally hazardous areas. Working in collaboration with the NHS, the firm has moved into the health sector and is installing its new range of products in hospitals in Dundee and across the UK. The units are made in Dundee using locally sourced materials, including flame-retardant PVC made by Angus firm Montrose Rope and Sail.

James Downie, a project manager at Starn, told the Dundee Courier: “The Safehouse habitats we provide to the energy sector are used for welding activities offshore and we have inline gas monitoring systems, so the air that’s fed into the habitat is monitored continuously. We create an overpressure in the habitat where hot work or welding is taking place, and this pushes any hydrocarbons away from the ignition source, which protects the person working within them.

“It also keeps the air free from toxic and flammable gases, so if any hydrocarbons are detected in the clean air, the sensor closes the damper and maintains the integrity of the habitat. We harnessed this technology and adapted it to provide safe environments for healthcare staff and patients.”

Work on novel ways of allowing dental practice to continue during the pandemic is increasing. Last month, researchers at New York’s Cornell University published proposals for a helmet “to contain pathogen-bearing droplets in dental and otolaryngologic outpatient interventions”.

Comments are closed here.